In recent years, there has been a significant advancement in the field of Artificial Intelligence (AI) and Augmented Reality (AR). These technologies have become increasingly popular and have the potential to enhance virtual experiences in various fields such as gaming, education, healthcare, and...

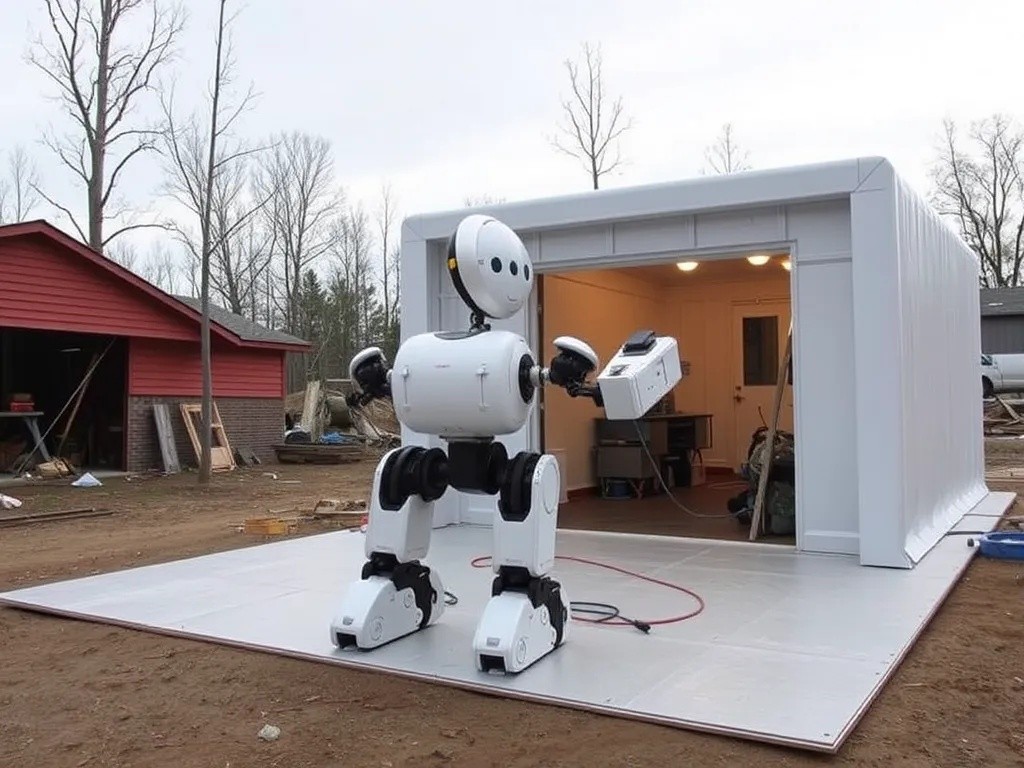

Robot Builder Constructs Emergency Shelters After Disasters

Natural disasters leave millions of people without adequate shelter each year, often in conditions where traditional construction is impossible due to destroyed infrastructure, dangerous conditions, or shortage of skilled workers. Autonomous construction robots are now being deployed to disaster zones to rapidly build emergency shelters, working continuously in harsh environments to provide safe housing when it is needed most urgently. These robots combine advanced engineering, artificial intelligence, and specialized construction techniques to transform disaster response and provide hope to displaced communities.

The Challenge of Post-Disaster Housing

After earthquakes, hurricanes, floods, or other catastrophic events, survivors often face weeks or months in temporary tents, exposed to weather, lacking privacy, and vulnerable to disease. Traditional emergency housing takes too long to construct, requires materials and workers that may be unavailable, and often proves inadequate for the climate or local conditions. Speed becomes critical as longer shelter delays lead to increased health problems, family separation, and community disruption.

Why Robots Offer Solutions

Construction robots address multiple challenges simultaneously:

- They work twenty-four hours daily without rest, dramatically accelerating shelter construction

- They operate in dangerous conditions unsafe for human workers, including unstable ground, contaminated areas, or extreme temperatures

- They require minimal existing infrastructure, bringing their own power and materials

- They maintain consistent quality regardless of pressure or difficult conditions

- They can be deployed within hours of a disaster, arriving by air transport before traditional construction equipment

How Robot Builders Operate

The autonomous construction system typically consists of several specialized robots working together as a coordinated team. Each robot handles specific construction tasks while AI coordination ensures efficient workflow and problem-solving when obstacles arise.

Site Preparation Robots

Initial robots scan and prepare construction sites using sensors and ground-penetrating radar to identify safe building locations, avoiding unstable soil, buried utilities, or hidden debris. These robots clear minimal areas needed for structures, level ground when necessary, and mark foundation locations with precision. They work much faster than manual site preparation while ensuring safety in environments where hidden hazards might endanger human workers.

Foundation and Structure Assembly

Once sites are prepared, construction robots begin assembling shelter components. Most systems use pre-fabricated modular pieces designed for rapid assembly rather than building from scratch. Robots unload materials, position foundation elements, and assemble wall panels, roof structures, and other components with precision. Advanced gripping systems handle various materials and shapes while sensors ensure proper alignment and secure connections.

The robots can adapt construction to terrain and conditions, adjusting designs when ground conditions require alternative approaches or when material availability differs from plans. This flexibility proves crucial in disaster zones where conditions rarely match pre-planned scenarios.

Materials and Design

Emergency shelters must balance rapid construction with durability, safety, and livability. Robot-built structures typically use lightweight composite materials that provide excellent insulation, weather resistance, and structural strength while remaining portable for robot manipulation. Panel-based designs allow modular construction where robots can complete basic shelters in hours and expand them as time and materials allow.

Climate-Adaptive Construction

The robot system includes a database of shelter designs optimized for different climates and conditions. In hot regions, it constructs shelters with enhanced ventilation and reflective surfaces to manage heat. For cold climates, it prioritizes insulation and weatherproofing. In areas with heavy rainfall, elevated floors and improved drainage prevent flooding. This adaptability ensures appropriate housing regardless of where disasters occur.

Power and Logistics

Construction robots operate primarily on battery power supplemented by portable solar panels, allowing deployment without reliable electricity infrastructure. Batteries are swapped by support robots or charged overnight via solar panels set up at the construction site. This energy independence proves essential in disaster zones where power grids remain damaged for extended periods.

Material logistics present significant challenges. The system typically brings standardized shelter components via cargo aircraft, with robots unloading and organizing materials autonomously. As local supply chains recover, robots can adapt to incorporate available materials, reducing dependence on external supplies. Some advanced systems include mobile fabrication units that produce components on-site from raw materials.

AI Coordination and Problem Solving

Central AI systems coordinate multiple robots working simultaneously across construction sites. The AI assigns tasks based on robot capabilities, material availability, and priority needs. It optimizes construction sequencing to minimize delays and maximize efficiency. When robots encounter problems such as damaged materials or unexpected site conditions, the AI system analyzes situations and develops alternative approaches without human intervention.

Learning from Experience

Each deployment improves future performance through machine learning. The system analyzes which construction approaches worked best in various conditions, identifies common problems and effective solutions, and refines designs based on real-world performance. This continuous improvement makes the robots increasingly effective with each disaster response.

Integration with Human Teams

Despite high automation, the robot systems work alongside human disaster response teams rather than replacing them. Human coordinators determine priority construction areas, interact with displaced communities to understand their needs, and make decisions about resource allocation. Local workers can assist robots with tasks requiring human judgment or cultural knowledge. This collaboration combines robotic efficiency with human insight and community connection.

Beyond Basic Shelter

As immediate shelter needs are met, construction robots can expand their role. They build community facilities like medical clinics, food distribution centers, and schools. Some systems include capabilities for utility infrastructure, installing water distribution systems, electrical wiring, and sanitation facilities. This expansion from emergency shelter to temporary communities helps restore normal life more quickly.

Real-World Deployments

Robot construction systems have been deployed in earthquake zones, hurricane-affected regions, and areas experiencing conflict-related displacement. Results show dramatic improvements in shelter provision speed, with robot teams completing in days what traditional methods required weeks to accomplish. Shelter quality exceeds standard emergency tents, providing better protection, privacy, and dignity for displaced families.

Cost Effectiveness

While initial robot system costs are substantial, per-shelter costs become competitive with traditional emergency housing when accounting for speed, quality, and reduced need for skilled labor in dangerous conditions. The ability to redeploy robots to multiple disasters increases their value compared to single-use shelter solutions.

Limitations and Challenges

The technology faces ongoing challenges including transport logistics for deploying heavy robotic systems to remote disaster sites, material supply chains that may be disrupted by the same disasters requiring shelters, and the need for technical support to maintain and repair robots in field conditions. Cultural acceptance varies, with some communities preferring traditional construction methods or materials even when robots offer advantages.

Future Directions

Development continues toward lighter, more versatile robots with enhanced problem-solving capabilities. Integration with drone surveys could allow robots to begin work while human teams are still mobilizing. Advanced materials research focuses on shelter components that robots can produce from local materials, reducing dependence on supply chains. The ultimate goal is self-sufficient construction systems that arrive quickly and build complete communities with minimal external support.

Robot builders for emergency shelters demonstrate how automation can address humanitarian challenges where time and conditions make traditional approaches inadequate. By providing rapid, safe, quality housing in the aftermath of disasters, these systems help communities begin recovery with basic dignity and security restored.