In recent years, there has been a significant advancement in the field of Artificial Intelligence (AI) and Augmented Reality (AR). These technologies have become increasingly popular and have the potential to enhance virtual experiences in various fields such as gaming, education, healthcare, and...

Utilizing AI and Robotics in Manufacturing: Optimizing Production Processes to Drive Enhanced Efficiency

In today's rapidly evolving technological landscape, the integration of Artificial Intelligence (AI) and Robotics in manufacturing has revolutionized the way businesses operate. By leveraging the power of AI and Robotics, companies can streamline their production processes, leading to increased efficiency and productivity.

AI has emerged as a game-changer in the manufacturing industry. With its ability to analyze vast amounts of data and make intelligent decisions, AI systems can optimize production workflows and identify areas for improvement. By implementing AI-powered predictive analytics, manufacturers can minimize downtime, optimize inventory management, and enhance overall operational efficiency.

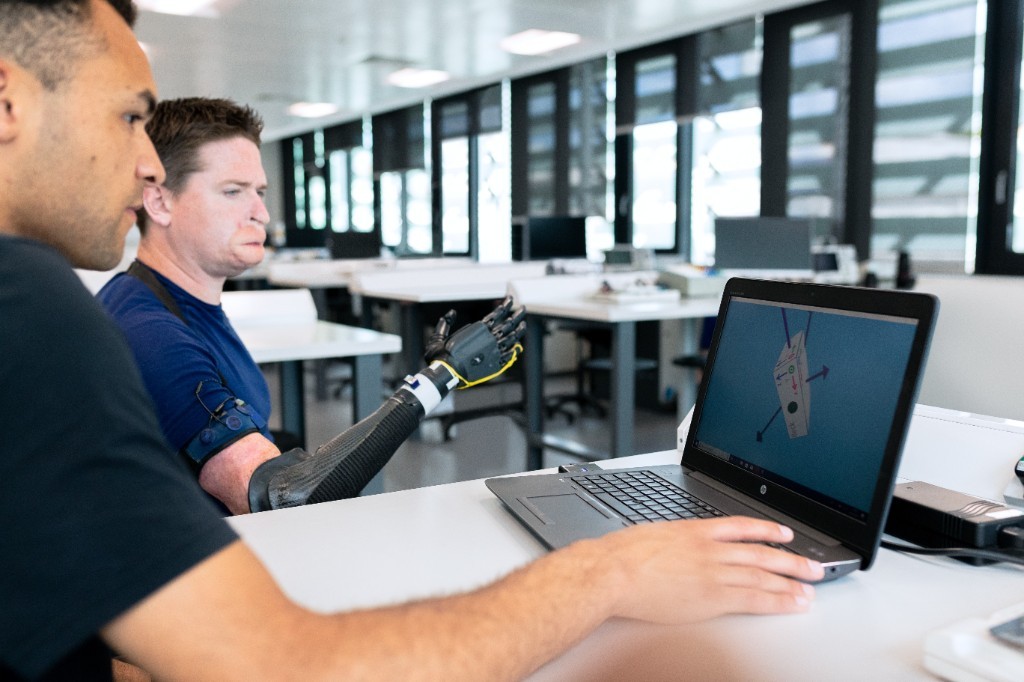

Additionally, Robotics has transformed the manufacturing landscape by automating repetitive and labor-intensive tasks. Robots can perform complex operations with precision and speed, reducing the risk of errors and improving product quality. By taking over mundane tasks, robots free up human workers to focus on more strategic and creative aspects of production.

The role of AI and robotics in manufacturing

AI and robotics have revolutionized the manufacturing industry by streamlining production processes and increasing efficiency. These technologies have transformed traditional manufacturing methods and have paved the way for a new era of automation and innovation.

One of the key roles of AI and robotics in manufacturing is the optimization of production processes. With the help of AI algorithms, manufacturers can analyze large volumes of data and identify patterns and trends that can lead to improved efficiencies. By automating tasks that were previously performed manually, AI and robotics can reduce human error and increase overall productivity.

Improving quality control

AI and robotics play a crucial role in improving quality control in manufacturing. These technologies can perform repetitive and tedious tasks with precision and accuracy, ensuring that products meet the desired standards. AI-powered vision systems can detect defects and abnormalities in real-time, allowing manufacturers to take corrective actions promptly.

Moreover, AI and robotics can also assist in predictive maintenance. By continuously monitoring equipment and analyzing data, these technologies can identify potential issues before they cause a breakdown or failure. This proactive approach to maintenance can significantly reduce downtime and production losses.

Enhancing safety

The use of AI and robotics in manufacturing also has a significant impact on safety. By automating hazardous tasks and removing human workers from dangerous environments, these technologies can minimize the risk of accidents and injuries. Robots can handle heavy lifting, repetitive motions, and exposure to harmful substances, enabling human workers to focus on more complex and value-added activities.

Furthermore, AI-powered safety systems can detect anomalies and alert operators in real-time, preventing accidents before they occur. These systems can monitor various parameters, such as temperature, pressure, and vibration, ensuring that machines operate within safe limits.

Enabling customization and flexibility

AI and robotics enable manufacturers to achieve greater customization and flexibility in their production processes. With the ability to adapt quickly to changing demands, these technologies allow manufacturers to produce a wide range of products efficiently. Robots can be programmed to perform different tasks and switch between them seamlessly, reducing the need for retooling and setup times.

In conclusion, AI and robotics have a transformative role in manufacturing. From optimizing production processes to improving quality control, enhancing safety, and enabling customization, these technologies have revolutionized the industry. As the capabilities of AI and robotics continue to advance, we can expect further advancements and innovations in the manufacturing sector.

Benefits of AI and Robotics in Manufacturing

AI and robotics have revolutionized the manufacturing industry, providing numerous benefits that have transformed production processes and increased efficiency. Here are some key advantages of incorporating AI and robotics in manufacturing:

1. Increased Efficiency

AI and robotics automate repetitive tasks, allowing for faster and more accurate production. This eliminates human errors and reduces the time required for manufacturing processes. With AI and robotics, manufacturers can achieve higher production rates and meet customer demands more efficiently.

2. Improved Quality Control

AI-powered systems can analyze data in real-time, enabling manufacturers to monitor and control the quality of products throughout the production process. This ensures that only products meeting the highest standards are delivered to customers, reducing the risk of defects and recalls.

3. Enhanced Safety

Robots are capable of performing dangerous and physically demanding tasks, reducing the risk of injuries to human workers. By using robots for tasks such as heavy lifting or working in hazardous environments, manufacturers can create safer working conditions and protect their employees from potential harm.

4. Cost Savings

Implementing AI and robotics in manufacturing can lead to significant cost savings. Automation reduces labor costs by eliminating the need for manual labor, and it also minimizes material waste by optimizing production processes. Additionally, AI-driven predictive maintenance can help prevent costly equipment breakdowns and reduce downtime.

5. Flexibility and Adaptability

AI and robotics provide manufacturers with the flexibility to adapt to changing market demands. With automated production lines, manufacturers can quickly reconfigure processes and switch between different product lines, allowing for faster product launches and more efficient use of resources.

6. Data-Driven Decision-Making

AI-powered systems can collect and analyze large amounts of data, providing valuable insights for decision-making. Manufacturers can use this data to optimize production processes, identify areas for improvement, and make informed decisions that drive efficiency and productivity.

7. Competitive Advantage

By leveraging AI and robotics, manufacturers can gain a competitive edge in the market. Increased efficiency, improved quality control, cost savings, and the ability to quickly adapt to market demands can help manufacturers stay ahead of the competition and attract more customers.

Conclusion

The benefits of AI and robotics in manufacturing are undeniable. By embracing these technologies, manufacturers can streamline production processes, improve product quality, enhance safety, reduce costs, and gain a competitive advantage. As AI and robotics continue to advance, the manufacturing industry will continue to evolve and achieve new levels of efficiency and innovation.